PINE BASED CHEMICALS FOR FLOTATION REAGENTS

FLOTATION COLLECTORS

Flotation collectors are commonly classified as anionic, cationic or non‑ionic. Anionic collectors are typically fatty‑acid‑based compounds, such as tall‑oil fatty acids (TOFA), and are widely used for the flotation of phosphate and many oxide minerals. Cationic collectors are typically amine‑based compounds, such as rosin‑derived amines, and are commonly applied to float quartz and other silicates, including in reverse flotation circuits.

Gum rosin and its derivatives chiefly comprise resin acids, notably abietic acid, and are applicable as reagents in the flotation of hematite, magnetite and goethite. These derivatives can be neutralised with caustic soda to form sodium soaps, for example DERCINATE 70D, a rosin soap produced by DRT®. TOFA is used in anionic collector systems; TOFA‑based pentaerythritol esters, such as RESINOLINE E500 from DRT®, are employed as frothing agents in mineral flotation.

Rosin amine is an important constituent in flotation reagent schemes and can effect the separation of pyrochlore from calcite, as well as silica (SiO2) from apatite, by flotation (British patent 800,717, 1958; Herbert G. Burks). A widely referenced commercial grade is Rosin Amine D, a rosin‑amine acetate produced by PDM Inc. The series typically contains approximately 55% dehydroabietylamine, 15% dihydroabietylamine, 15% tetrahydroabietylamine, 8% pimaricamine and 7% isopimaricamine.

NOTE: DERCINATE and RESINOLINE is the trademark of DRT®. Roins Amine D is the trademark of PDM® Inc.

MARKET REPORT: Global Mining Chemicals Market Outlook (2014-2022)

Pine Based Chemicals For Flotaion

| Available Products | CAS | Sales Region |

| Disproportionated Rosin | 8050-09-7 | Global |

| WW Grade Gum Rosin | 8050-09-7 | Global |

| WG Grade Gum Rosin | 8050-09-7 | Global |

| 50% Pine Oil | 8002-09-3 | Global |

| 65% Pine Oil | 8002-09-3 | Global |

| Crude Tall Oil | 8002-26-4 | Asia, Middle East |

| 2nd Grade TOFA | 61790-12-3 | Asia, Middle East |

| 3rd Grade TOFA | 61790-12-3 | Asia, Middle East |

Application Range

| Ore | Cationic Collector | Anionic Collector | United Cationic & Aninoic Collector |

| Chrysoberyl | √ | ||

| Collophane | √ | ||

| Hematite | √ | ||

| Jasper | √ | ||

| Lepidolite | √ | √ | |

| Limonite | √ | ||

| Magnetite | √ | ||

| Quartz | √ | ||

| Siderite | √ | ||

| Silicates | √ | ||

| Specular stone | √ | √ | |

| Sulfide | √ | ||

| Vanadium concentrate | √ | ||

| Zinc oxide | √ |

PINE BASED CHEMICALS ON FROTHERS/SURFACTANTS

In mining chemicals, turpentine oil is a key frother, commonly referred to in China as “Number 2 oil”. It naturally contains terpineol, produced industrially via hydration–dehydration of α‑pinene and β‑pinene. Turpentine oil is generally classified as gum turpentine, crude sulphate turpentine (CST) and wood turpentine. In North America, CST is a papermaking by‑product and is widely used as a primary feedstock for frother manufacture.

Frothers control bubble size distribution and froth quality. They also affect bubble–particle attachment, promoting recovery of hydrophobic particles on small, stable bubbles, while aiding the rejection of entrained hydrophilic gangue through appropriate froth drainage.

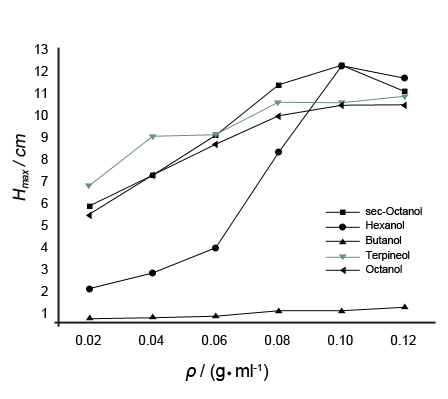

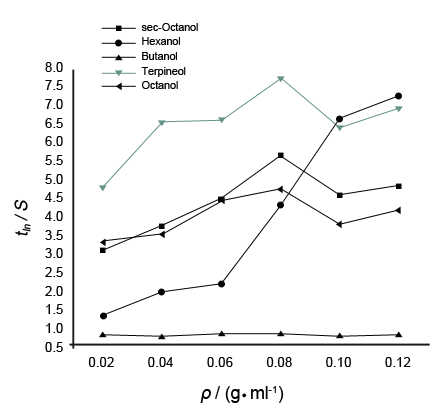

Terpineol is a cyclic alcohol bearing a hydroxyl group on a six‑membered ring with an unsaturation, giving a comparatively rigid molecular architecture. In flotation systems, it often provides greater foam‑film stability than linear alcohols. This cyclic structure can reduce bubble‑film flexibility and help the froth maintain its structure through enhanced interfacial elasticity. As shown in the figures below, terpineol typically yields moderate froth height and improved foam half‑life across a range of concentrations when compared with other alcohols.

Get the Quote

Contact our sales team to get the latest product specifications and product quotes.