Modified Rosin Phenolic Resins

The excellent high polymer binders for inks

FOREVEREST® Modified Rosin Phenolic Resins are made by gum rosin and through the condensation-polymerization process with alkylphenols, formaldehyde, polyol and other ingredients. It has characters of high molecular weight, low acid value, and honeycomb structure. The honeycomb structure is usually applied on offset printing inks, binding pigments and adhesives to keep moist and adhesion.

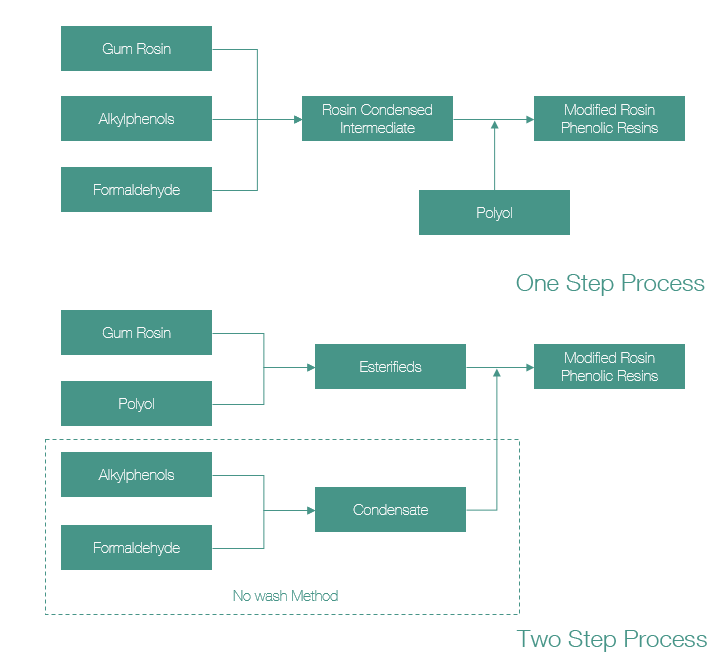

The synthetic of rosin modified phenolic resin mainly using two processes. One-Step Process is used alkylphenols, formaldehyde, polyol and other ingredients reacting with gum rosin directly. The waste is evaporated from the reaction. So this process can keep environment-friendly. But the phenolic condensation of gum rosin would produce other side effects due to the high temperature or dissolve unevenly when melting. It resulting in inconsistent quality.

Two-Step Process has a pre-synthesis reaction. Synthesize the phenol-formaldehyde condensation oligomer in No-wash Method firstly. This intermediate is made by an effected catalyst and solid formaldehyde (content of ≧90%), which has a stable structure and composition. Then reacted with gum rosin. The processing is easy to control quality in each step. Use Two-Step Process will reduce reaction hours (reduce 6 hours compare with Washing Method) and keep environment-friendly.

Technical Advice

Kindly contact us if you are interested in the business in this market.

EXPLORING THE MODIFIED ROSIN PHENOLIC RESINS

LEARN SOLUTIONOUTREACH THE TACKIFIER MARKETS

LEARN SOLUTIONGet the Quote

Contact our sales team to get the latest product specifications and product quotes.