Industry News, Adhesives & Sealants & Tackifiers, Coatings, Cosmetics & Persnoal Cares, Flavor & Fragrance Industry, Inks

Progress on the patents about the modifications of gum rosin and their applications

Industry News, Adhesives & Sealants & Tackifiers, Coatings, Cosmetics & Persnoal Cares, Flavor & Fragrance Industry, Inks

Gum rosin is widely used in various industries due to its excellent antiseptic, insulating, bonding properties. However, there are three disadvantages limiting its applications:

To overcome these, it is necessary to modify gum rosin.

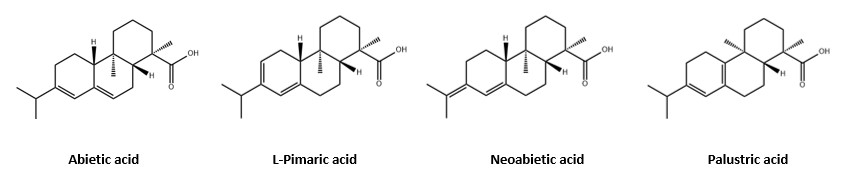

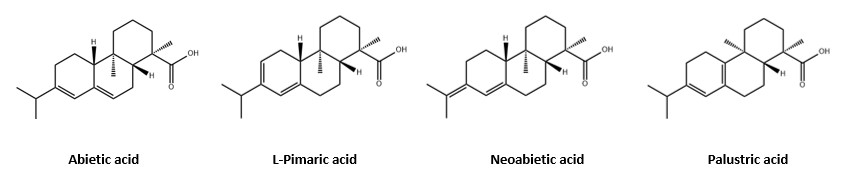

Gum rosin mainly contains resin acid with Alkyl hydrogenated phenanthrene structure (abietic acid, L-pimaric acid, palustric acid, neoabietic acid and etc). Based on its structure, there are two modification methods:

The modification degree and methods can be adjusted based on specific requirements, so as to give gum rosin the desired properties.

The progress on the modifications of gum rosin and their applications are summarized as follows:

| Modification type | Modified Rosins type | Patents | |

| 1.Modification on double bond | 1.1.Fortified gum rosin:

Typical fortified rosin is synthesized via Diels-Alder reaction of gum rosin with fumaric acid or maleic acid. They are one of the largest and most wide-used modified rosins. The water-based emulsions with fortified rosin as carrier resin are widely used in inks and sizing agent. |

l Oct 1992 | Hutter et al. published a patent regarding the synthesis of a water-soluble Rosin polyamide resin. It is used in packaging ink, with good adhesion, wettability, and heat stability. |

| l Feb 1993 | El-Hefnawi et al. invented a Rosin carboxylate modified polyamide/acrylic resin for printing ink. | ||

| l Jun 1993 | Shah et al. published a patent about the creation of one fortified rosin-based emulsion polymer which could be used in various printing ink and lacquer. | ||

| l Apr 1994 | Hutterand and G.Frederick issued a patent about a rosin-based amino emulsion polymer for inks. | ||

| l Dec 1995 | Hutterand and G.Frederick published another patent regarding polyvinyl alcohol modified rosin-based emulsion polymer, used in making gravure inks and offset inks, with excellent printing property. | ||

| l Mar 1996 | Another patent about an adduct of rosin and Hydroxycarboxyl pyrrolidone for making acrylic-based emulsion used in flexographic ink and gravure inks was issued by Hutterand and G.Frederick. | ||

| l Aug 1997 | Another patent from Hutterand and G.Frederick about rosin ester-amino compounds carrier resin for making acrylic emulsion was published. It is used in water-based flexographic ink and gravure inks. | ||

| l Dec 1997 | A Urea or carbamate modified rosin emulsion polymer was invented by Hutterand and G.Frederick for producing water-based inks used in adhesive and extruded complex printing.

|

||

| l Apr 2002 | Roberts et al. created a rosin emulsion for making a paper sizing agent. Compared with traditional Anionic dispersant and Casein stabilizers, it has a higher sizing efficiency, but lower cost. | ||

| l Jun 2003 | Gaudl and Kai-Uwe published a patent about the synthesis of

Acrylate and maleic modified rosin, used in environment-friendly printing inks. |

||

| 1.2.Rosin-vinyl polymers: | l May 1991 | Burke et al. published a patent regarding rosin modified styrene-acrylate resin, applied to the synthesis of toner. Its excellent compatibility with various polymers, toner dispersions, nitrocellulose help reduces fogging and tailing. | |

| l Oct 1996 | Schilling and Peter issued a patent about a polyamine condensate of the copolymer of styrene-acrylic acid with gum rosin, used as corrosion inhibitor for metallic surface, presenting excellent film moldability and film durability. | ||

| l Jan 2001 | Shah et al. create a gum rosin-fatty acid vinyl polymer, used as a sizing agent for the cellulosic material surface. This polymer can reduce the use level of Initiator and chain transfer agent thus lowering the cost and reducing unpleasant odor. | ||

| l Dec 2001, Aug 2002 | Shah et al. found the new applications for the gum rosin-fatty acid vinyl polymer they created, including anti-water-evaporation coating for paper and other cellulosic materials, ink additives, coating additives, abradant for ink and coating and etc. | ||

| l Aug 2002 | Hutter and G. Frederick issued a patent of an emulsion of polymer of rosin-fatty acid vinyl/polyamide resin for printing in and coating. | ||

| l May 2004 | Hutter and G. Frederick issued another patent of rosin-fatty acid vinyl/polyamide resin, to improve the adhesion of water-based inks and coatings applied on a plastic substrate. | ||

| 1.3.Rosin modified phenolic resin:

It is widely used in adhesives, printing inks and coatings |

l Aug 1989 | DeBlasi et al. published a patent regarding a Rosin modified phenolic resin for printing ink. It has good weatherability, printing and reproduction ability. And due to its low cost and uniformity, it is widely found application in gravure printing inks as a binder. | |

| l Apr 1995 | Womack and Gary B. issued a patent about a phenolic modified rosin/DCPD resin. It is suitable for offset printing ink, with better viscosity and solubility than traditional maleic modified rosin/DCPD resin. | ||

| l Jun 1995 | Crews et al. published a patent about the synthesis of a rosin-modified phenolic resin and the improvement for the stability of its viscosity. | ||

| l Feb 2000 | Frihart et al. created light-color, low-Mw rosin modified phenolic resin mainly made from gum rosin, phenol, formaldehyde, and glycerin, used as tackifier for adhesives. | ||

| l Nov 2000 | Michael D. et al. issued a patent of rosin modified phenolic resin elastomer made from butadiene homopolymer, rosin modified phenolic resin, MA and polyols, used as the base material in pigments for offset printing ink, showing good wear resistance. | ||

| l Jan 2001 | Matzinger and Michael D. issued a patent about a rosin modified phenolic resin made from nonylphenol, formaldehyde, rosin, and pentaerythritol. It is used as a binder for offset printing ink and lacquer due to its good chemical and physical property. | ||

| 1.4.Hydrogenated Rosin:

After modifications (esterifying and etc), hydrogenated rosin can be used in toners and anti-reflection coatings. |

l Jan 1991 | Matsumura et al. published a patent regarding a polyester made from rosin or hydrogenated rosin, used as a binder for toner particles applied in fast printing, with low-temperature stability and good compensating resistance. | |

| l Apr 2002 | Tomo and Yoichi issued a patent about an anti-reflection coating made from hydrogenated rosin, Pyrophenol, and bisphenol A, used as a photoresist for photolithography, as well as in semiconductor devices. | ||

| 1.5.Polymerized Rosin: The stability of polymerized Rosin can be improved via disproportionation. It can be applied directly or after esterifying. | l Jun 1991 | Hollis et al. published a patent about the stability of a polymerized rosin. It proved that polymerization can lower the oxidation trend of rosin in the air and improve its color stability | |

| l Jan 1992 | Minn and James published a patent to improve the color stability of polymeric rosin with sodium hydroxymethanesulfonate. | ||

| 2.Modifications on carboxyl: esterification, reduction, amidation and etc | 2.1.1.Polyhydric alcohol ester of rosin

(2.1. Rosin esters: The esterification products include Polyhydric alcohols (glycerol, pentaerythritol, etc.) esters, alkyl (C12 ~ C22) alcohol esters, enol esters and other (phenol, hydroxylamine) esters. They are also one of the most important modification products group which are widely used in inks, coatings, paper, rubber.)

2.1.2.Alkyl alcohol ester

2.1.3. other esterified rosin

|

l Nov 1992 | Johnson, Jr and Robert W. issued a patent about a light-color glycerol ester of gum rosin, as a tackifier for hot melt adhesive. |

| l Jan 1995 | Maeda et al. published a patent about making a colorless and odorless rosin ester by disproportionation and hydrogenation. It could be used in hot melt adhesive and pressure-sensitive adhesive as tackifying resin, road marking paint, paper as a sizing agent and synthetic rubber as an emulsifier. | ||

| l Apr 1996 | Schluenz. et al. issued a patent about pentaerythritol ester of gum rosin, used as tackifier for adhesive and emulsifier for synthetic rubber. | ||

| l Sep 1996 | Hemmings et al. published a patent about a rosin ester derivative surfactant. It could be used as a water-based dispersant in PSA, with at least 6months shelf life, low foam and good shear stability. | ||

| l Sep 1996 | Williams and Theodore J. created a partially esterified fortified rosin with low viscosity and long shelf life, used as a binder for inks. | ||

| l May 2003 | Frihart et al. published a patent of a light-color rosin ester (tall oil rosin with Pentaerythritol or 1,4-cyclohexanedimethanol), used as tackifier for packaging adhesive, PSA, cosmetic and etc. | ||

| l Aug 1991 | Wideman et al. issued a patent about alkyl alcohol (C12~C22) ester of rosin, which could be used as an additive of vulcanized rubber. Compared with traditional complex additive, it not only lower the cost with a single ingredient but also improve the properties of rubber and avoid the harmful reactions brought by the complex additive. | ||

| l Aug 1991 | Wideman. et al. issued a patent related to the preparation of p-hydroxydiphenylamine ester of rosin acid, used as a rubber additive. | ||

| l Sep 1993 | Wideman et al. published a patent about a derivative of dicyclopentadienol ester of rosin, used as an additive or auxiliary oil in rubber making, replacing Paraffin or petroleum, to improve the peel strength and friction resistance of rubber. | ||

| l Apr 1996 | Sandstrom et al. published a patent about a monoester of rosin acid used as a rubber additive or auxiliary oil. Adding monoester of rosin acid in the vulcanization stage of rubber can enhance the elastic modulus and tear strength of rubber. | ||

| 2.2.Rosin amide | l Sep 2002 | Ones and Raymond H. invented a polymer of rosin amide-amine/polyethylene amine and multi-function acrylate which could be used in offset and gravure printing ink due to its high softening point. It also has good hydrophobicity, UV-stability, as well as good adhesion for metal surfaces. | |

| 2.3.1.Rosin imide

(2.3. Rosin amine: mainly used for rubber making.) |

l Jul 1992 | Sandstrom and Paul H. published a patent of N-rosin malebutenediimide, used as an additive or auxiliary oil for rubber making, to improve the peel strength and friction resistance of rubber. | |

| l Jun 2002 | Wideman and Lawson Gibson et al. issued a patent related to the preparation of a rosin modified succinamide acid, used as rubber additive. It can reduce the rubber rebound value, increase the traction of the tire. | ||

| 2.3.2.Rosin isocyanate | l Nov 2005 | Kunisch et al. created a rosin amine derivative antifouling agent. As an active agent, it can prevent the adhesion of aquatic organisms on the surface of submerged structures (vessel, pier, wharf and etc), also being environmental-friendly. Rosin isonitrile, rosin isonitrile salt, or rosin thiocyanate can also be used as antifouling agents. | |

| 3.Other rosin derivative | Other rosin derivative | l Apr 1998 | Huang et al. published a patent about the preparation of a cationic emulsion modified rosin emulsion. It can significantly improve the stability of rosin emulsion, its compatibility with anion starch solution, mobility of paper machine, so as to improve the sizing efficiency on the acidic or alkaline surfaces. |

| l Mar 2005 | Martz et al. published a patent related to the preparation of rosin-modified amino plastic adhesive. The powder coating presents good properties, high stability and also being easy to use after adding this rosin-modified amino plastic. | ||

Overall, the modification of gum rosin focuses mostly on the applications on paper sizing (to control the adsorption of paper to water), printing ink, adhesive (functioning as tackifier), rubber (functioning as additive), as well as anti-fouling agent, plastic, pigment and etc.

As the research on gum rosin develops in-depth, the applications of gum rosin present two distinct features: The acknowledged applications are constantly being refined and improved; the new applications are also continuously being extended.