Company News, PR

How to choose tackifier resins for Non-woven adhesives

Company News, PR

A report from “MarketsandMarkets” estimated that “The global Non-Woven adhesives market size is to reach USD 2.22 billion by 2020, registering a CAGR of 8.65% between 2015 and 2020, with the global rising demand especially in Asia-Pacific.” “High elasticity, optimum performance, safe products, reduced fluff, and easy-to-use are major drivers for the Non-Woven adhesives market”.

Non-Woven adhesives are used in many applications such as baby care, feminine hygiene, adult incontinence, and others (medical product, pet care, bath tissue, and other small applications). Baby care is the largest one.

SBC-based adhesives and APAO-based adhesives are two main types of adhesives for Non-woven market.

SBC-based adhesives, the hygiene products uses primarily SBS/SIS-type hot melts for their ability to retain flexibility and elasticity at low temperatures. They are generally the least expensive adhesives, usually have high initial tack strength, while tend to harden (and lose adhesion) over time, especially exposed to sunlight and weather.

> SBS: Styrene-butadiene-styrene

> SIS: Styrene-isoprene-styrene

> SEBS: Styrene-ethylene/butylene-styrene (SEBS), the hydrogenated form of SBS

> SEPS: Styrene-ethylene/propylene-styrene (SEPS), the hydrogenated form of SIS

APAO-based adhesives, Amorphous polyalpha olefins (APAO)-based adhesives are non-crystalline adhesives that remain soft, tacky, and flexible giving longer open times and good adhesion. It provides better moisture resistance, chemical resistance, heat resistance with especially lower odor and VOCs compared to SBC-based adhesives. The main manufacturers of APAO polymers include Evonik, Eastman, REXtac and Qida Chemical.

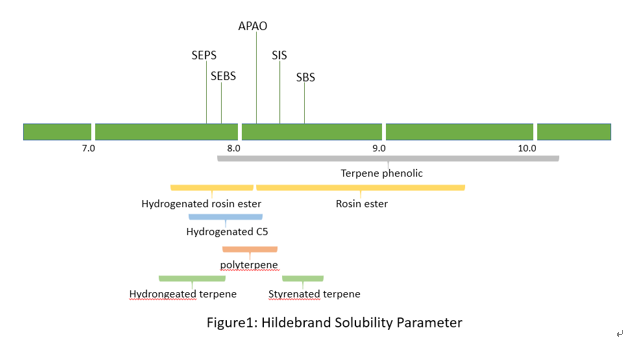

Tackifier resin is a key raw material in Non-woven adhesives other than base polymers. The performance characteristics of a tackifier resin in a polymer system, are directly related to the compatibility of the tackifier resin with the polymer. One can either employ solubility parameters or other guides to estimate the compatibility of a tackifier with a certain polymer. However, usually trial and error testing is required. Materials that possess similar solubility parameters are generally assumed to be compatible with each other. Image below illustrates the tackfier resin compatibility for SBC’s and APAO’s.

Figure.1 Hildebrand solubility parameter of common tackifiers © Foreverest Resources Ltd.

Foreverest® supply various resins for Non-Woven adhesives (Table 1, especially the extra-light color hydrogenated rosin esters/terpene resins, which were designed for high-performance hot-melt pressure sensitive adhesives (HMPSA) for disposable hygiene market. Key benefits of extra-light color hydrogenated tackfier resins include:

| Tackifier Type | CAS Number | Chemicals Name | Softening Point, R&B, °C |

Acid Value, mgKOH/kg |

Color, Gardner |

| Rosin Ester Based | 8050-31-5 | Glyceryl Rosinate | 85 to 95 | 10 max | 1 to 5 |

| 65997-13-9 | Glyceryl Hydrogenated Rosinate | 85 to 105 | 10 max | 1 to 5 | |

| 8050-26-8 | Pentaerythritol Rosinate | 90 to 115 | 15 to 25 | 1 to 5 | |

| 64365-17-9 | Pentaerythritol Hydrogenated Rosinate | 90 to 115 | 15 to 25 | 1 to 5 | |

| 9006-47-7 | Polymerized Rosin Ester | 100 to 160 | 10 to 25 | 8 to 10 | |

| N/A | Maleic Modified Rosin Ester | 95 to 145 | 15 to 45 | 3 to 6 | |

| Terpene Phenolic Based | 68648-57-7 | Terpene Phenolic Resin | 100 to 130 | 1 max | 7 to 9 |

| 68648-57-7 | Terpene Phenolic Resin Emulsion | 95 to 105 | N/A | N/A | |

| 106168-39-2 | Hydrogenated Terpene Polymer | 100 to 110 | 1 max | 50 max, Hazen | |

| 31393-98-3 | Polyterpene Resin | N/A | 1 max | 4 to 6 | |

| 31393-98-3 | Polyterpene Resin | 120 to 165 | 1 max | 7 to 10 | |

| Styrenated Terpenes based | N/A | Styrenated Terpene Resin | 75 to 120 | 1 max | 3 max |

1. Non-Woven Adhesive Market by Type Global Forecasts to 2020, MarketsandMarkets, Date: 24-Feb-2016, No. of pages: 129

2. Select Styrene Butadiene Copolymer Resin

3. Additive Advances via ASI