Feature Article, Company News, PR

The Characteristics of Hydrogenated Terpene Phenolic Resin.

Feature Article, Company News, PR

Hydrogenated terpene phenolic resin is a variation of terpene phenolic resin derivative that has been chemically modified through a hydrogenation process. This modification results in improved thermal stability, color stability, and resistance to oxidative degradation compared to non-hydrogenated terpene phenolic resins. While both hydrogenated terpene phenolic resin and terpene resins are derived from natural sources, hydrogenated terpene phenolic resins offer superior technical properties compared to non-hydrogenated terpene resins.

Terpene resin has many excellent properties, but it is not easily soluble in aromatic solvents and polar solvents, and its bonding strength is not strong enough. By introducing a phenolic group to prepare terpene phenolic resin, its polarity is increased, making it compatible with most film-forming substances.

Terpene phenolic resin is an excellent thickener for acrylic resins, butyl benzene rubber, natural rubber and chlorinated butyl rubber. This resin product has high compatibility with resins and rubbers, as well as strong bonding strength, large cohesive force and high temperature resistance. It performs better in hot melt adhesives, sealants, pressure-sensitive adhesives and sanitary materials. Due to its outstanding electrical insulation performance and water/weather resistance performance, it will also have broad development prospects as an adhesive applied in the hygiene products industry and electronic industry.

The terpene phenol resin has excellent performance. However, due to the double bond structure in the contained phenol and terpene, it is easily oxidized, resulting in a darker product color. Moreover, the presence of double bonds in the terpene structural unit affects its stability and weather resistance, limiting its application range.

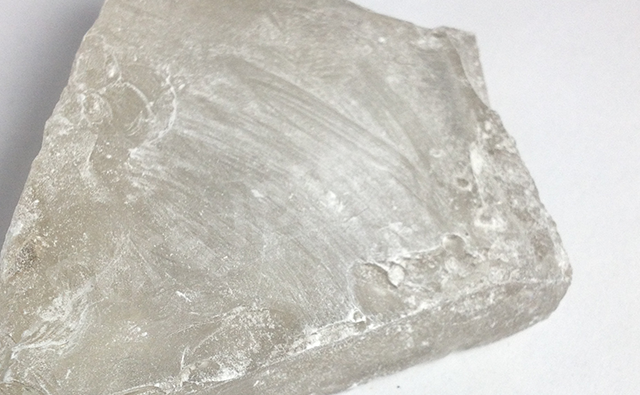

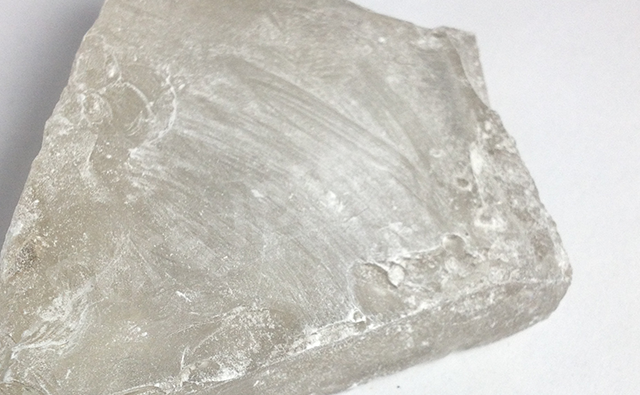

To create a stable hydrogenated terpene phenol resin with a light color, start by crushing the resin into powder. Then add solvent, catalyst, catalyst carrier, and stabilizer to the powder. Inject hydrogen gas and heat the mixture to obtain a melted product after reaction.

After releasing the pressure, the mixture is cooled down and discharged. Then, it undergoes filtration to remove the catalyst, catalyst carrier, and stabilizer. The resulting product is distilled to eliminate the solvent and obtain a highly stable hydrogenated terpene phenol resin with an ultra-light color. This preparation process yields a lightly colored hydrogenated terpene phenol resin that exhibits excellent stability and weather resistance. Moreover, these preparation steps are simple and environmentally friendly without causing pollution.

FOREVEREST® can supply ultra-light color and highly stable hydrogenated terpene phenolic resin, with Hanzen color number 100 and a softening point between 110℃~120℃. It can be used in the fields of optical PSA and adhesives, transparent coating agents, photosensitive materials, inks, and coatings.