Company News, PR, International Trade

Handling Guide of Loading 20*1000L IBC Tanks in 20ft Container

Company News, PR, International Trade

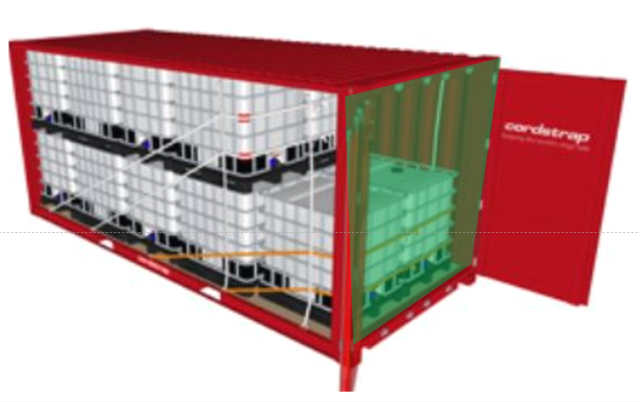

The liquid chemicals supplied by Foreverest Resources are sometimes packed in IBC tanks for shipping according to buyer requirements. Such as Gum Turpentine, a T.E.U (twenty feet equivalent unit) usually only loads 18*1000L IBC tanks (Figure 1). In recent years, COVID-19 has had a logistical impact on the global supply chain, resulting in continued high ocean freight rates. How to load and unload 20*1000 liter IBC tanks in a 20ft container becomes a pragmatic and worthwhile issue.

Figure 1. Side view of a 20ft containner with 18*IBC tanks inside. Picture source via https://cargorestraintsystems.com.au/

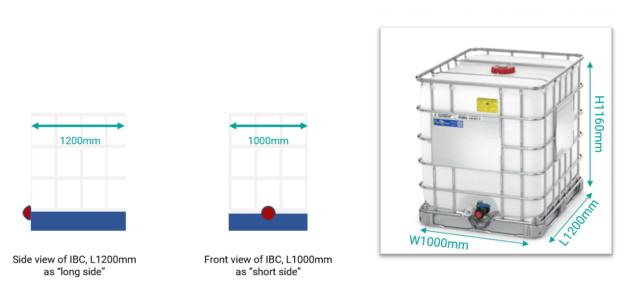

In general, a 20ft container is L6058mm*W2438mm*H2591mm. Its inner size is L5898mm*W2352mm*H2385mm. A regular 1000 liter (275gal) IBC tank is L1200mm*W1000mm*H1150mm (with pallet). In our case, we package the liquid chemicals by Schutz® MX1000 IBC ECOBULK. The MX1000 is L1200mm*W1000mm*H1160mm (with pallet), which is 10mm higher than a traditional IBC tank.

The height dimension of the door frame size of the 20ft container is W2286mm*H2261mm (Figure 2), which needs the forklift driver quite skillful when loading the last four IBC tanks and unloading the first four IBC tanks.

Figure 2. The door frame size of a 20ft container. Picture source via https://cargorestraintsystems.com.au/

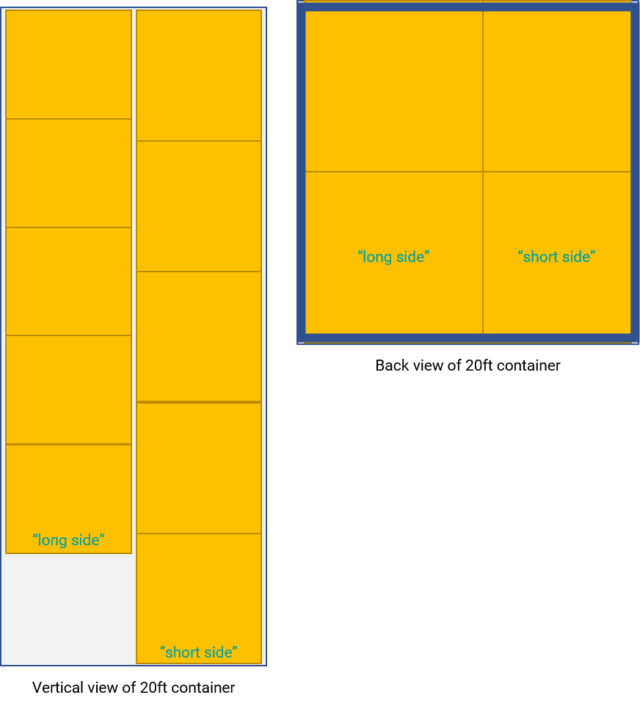

One IBC tank is L1200mm*W1000mm. When “Front-viewing” it, its cross-sectional width is 1000 mm, which is the “Short side”. When it is rotated 90 degrees and “Side-viewing” it, its cross-sectional width is 1200 mm, which is the “Long side” (Figure 3). Taking advantage of IBC size, it can load up to 20*IBC tanks. (Figure 4)

Figure 3. The “Long side” and “Short side” of IBC, Source: Schutz® MX-EX ANTISTATIC 1000 in this case. Edited by Foreverest.

Figure 4. IBC loading sketch map. Edited by Foreverest.

Here are the details and tips for reference when working:

Here are the details and tips for reference when working: