Industry News, Inks

The Packaging Ink Market in 2023

Industry News, Inks

Feature image copyright belongs to inkworldmagazine.com

The packaging printing industry is a huge market, with estimates placing the market at approximately $200 billion in the US alone. Corrugated printing is considered to be the largest segment, with flexible packaging and folding cartons close behind.

Inks plays a critical role and are varied depending upon the substrate. Corrugated printing typically uses water-based inks, while solvent-based inks are the leading ink type for flexible packaging and sheetfed and flexo inks for folding cartons. UV and digital printing are also picking up share, while metal deco inks dominate beverage can printing.

Even during COVID and the difficult raw material situation, the packaging market continued to grow. Packaging ink manufacturers report that the segment continues to do well.

Siegwerk CEO Dr. Nicolas Wiedmann reported that the demand for packaging and packaging inks further stabilized throughout 2022, with some softer months at year end.

“Nevertheless, the volatile economic environment of the last two years has definitely put all market players under high pressure,” added Dr. Wiedmann. “Ongoing effects of the COVID pandemic, continuously rising raw material and utility costs and finally the war in Ukraine have all made 2022 another challenging year full of uncertainties that hit the industry quite hard.”

The Siegwerk CEO noted that the ability to react quickly and adapt to rapidly changing circumstances has never been more important for companies as during that time.

“Despite all economic challenges throughout the year, we were able to manage mitigating the negative effects as much as possible, ensuring a continuous serving of our customers,” Dr. Wiedmann said. “And although we were not able to fully meet our performance targets for the year, we still made important progress on our sustainability agenda and further expanded our company’s global footprint. With the successful acquisition and integration of La Sorgente, an important ink supplier for flexo printing in Italy, we further strengthened our position in the European packaging market.”

Jim Felsberg, field marketing manager, Sun Chemical, said that 2022 was a year of transition.

“At the beginning of the year, the packaging ink market dealt with a variety of challenges that continued from 2021,” Felsberg added. “From rises in raw material costs to supply chain stoppages and increased freight costs, the industry saw a limited supply and struggled to find carriers to move products. As 2022 wrapped up, the challenges around supply chain issues lessened to a certain degree and we hope to see continued stabilization in the supply chain as we enter 2023.

“Though growth in the packaging ink market was flat to negative due to shortages in print materials, such as films and solvents, market demand was resilient in 2022,” added Felsberg.

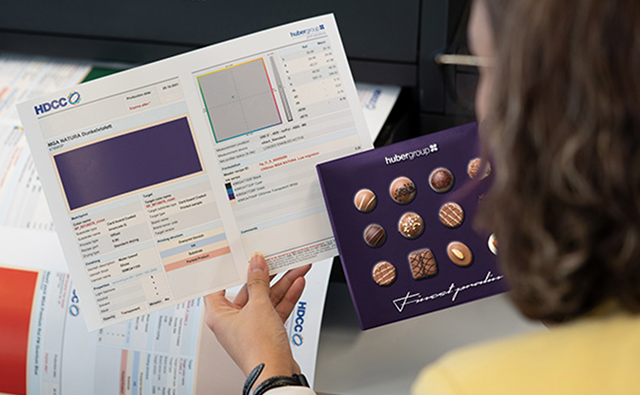

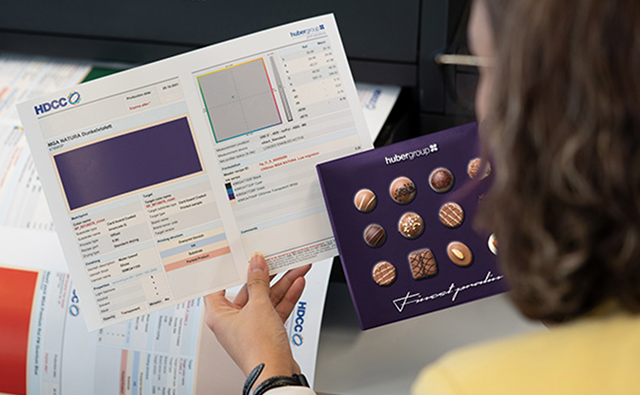

Dr. Lutz Frischmann, global product director flexible packaging for hubergroup, reported that the flexible packaging sector recorded slight growth within the past year.

“However, the market has remained under great pressure due to heavily increased prices and the continued constraints in the availability of raw materials,” Dr. Frischmann said. “We expect the market to continue to grow in the coming years.”

Dr. Frischmann noted that sales of water-based printing inks and varnishes segments also continued to grow slightly. “We believe that this originates from an increase in the corrugated and generally paper-based segment,” Dr. Frischmann said. “In the flexible packaging segment, water-based products still play a minor role because of energy and water treatment related issues. As in previous years, we also observed a strong increase in the global UV flexo market in 2022.”

Carsten Zölzer, president division offset and president Central & West Europe at hubergroup, noted that hubergroup still observes a slight increase in traditional offset printing, which is driven by the general trend towards folding carton packaging.

“UV sheetfed offset printing also continued to grow in the packaging market while the market for commercial printing is already saturated in Europe,” added Zölzer.

Doug Aldred, chief commercial officer for Flint Group, noted that continued global inflation is affecting the market overall, adding that the industry is resilient and is faring well.

“The packaging industry as a whole is gaining increased visibility by consumers worldwide who are continually more concerned about sustainability and recycling,” said Aldred. “Packaging applications are moving between substrates due to sustainability and functional performance characteristics. In response, companies in the packaging value chain are focused on accentuating the value of packaging and providing sustainable solutions that address consumer concerns.”

There are many growth areas in packaging, from folding cartons to flexible packaging and digital printing. Dr. Frischmann noted that the paper packaging segment is gaining market share.

“We observe a trend from film to paper packaging, as the latter is convincing with its good recyclability,” Dr. Frischmann said. “When it comes to foil-based packaging, we can see an increasing interest in mono-material packaging which can be recycled more easily.”

Aldred pointed out that the focus by consumers, brand owners, and package printers on sustainability is impacting substrate formats across all packaging applications.

“Overall, there is a drive for more innovative options for consumer ease of use or to focus on reduced energy consumption (transport), or ease in recycling,” he added, noting that fiber-based materials are replacing some flexible films, while lighter weight, flexible film, materials, such as pouches, are replacing glass and plastic bottles. Aldred also pointed to increasing interest in mono materials for flexible packaging,

“In addition, the need for inks and coatings to support food-safe packaging continues to be a focus,” Aldred noted.

Doneck Euroflex S.A. managing director Arndt Breitbach said Doneck expects that paper packaging will be pushed forward in the future.

“It is important that the packaging industry finds an answer to the necessity to establish a circular economy for plastic materials,” Breitbach added. “We are just about at a starting point of this development.”

Felsberg said that the major growth in 2022 was centered around sustainable packaging, from compostable packaging using third party certified inks to recyclable packaging and the removal of layers of the package.

“The focus of the growth was around one or more segments of sustainable packaging,” said Felsberg. “Sun Chemical has developed multiple solutions for sustainable packaging with a synergistic technology approach of inks, coatings and adhesives that uniquely allow the package to retain shelf appeal and meet industry sustainability goals.”

“Packaging plays an indispensable role in our everyday lives, and the demand continues to grow – not least due to increasing online trade,” Dr. Wiedmann said. “Whether folding cartons or flexible packaging, the trend is clear: sustainable and eco-friendly packaging solutions are required.”

Dr. Wiedmann said that there is great growth potential in both types of packaging as long as they are designed for recyclability and circularity in the sense of sustainability.

“Here, innovative and eco-friendly inks and coatings can improve the performance and recyclability of packaging and support the development of new circular packaging solutions by closing technical gaps and boost the use of renewable packaging materials,” Dr. Wiedmann said. “That’s why we are continuously driving the development of eco-friendly inks and coatings. Today, we already offer a wide range of circular solutions that enable the design of sustainable packaging concepts as folding cartons and flexible packaging in the sense of a Circular Economy.”

Leading ink manufacturers all report that sustainability has become a major point of emphasis among themselves and their customers.

Dr. Nikola Juhasz, global technical director of sustainability, Sun Chemical, noted that Sun Chemical’s sustainability approach is a full value-chain and life-cycle oriented approach, with the company collaborating up, down and across its various supply chains to deliver solutions.

“For example, how our products affect the waste management community, which ultimately must collect, sort and process finished products after their useful application lifetimes, is increasingly important in order to achieve the vision of circularity,” Dr. Juhasz said. “We are active participants in several global cross-industry organizations, such as the Association for Plastic Recyclers, which are focused on the future of packaging from a design for sustainability perspective. Members work together to understand and define the unique requirements to manage a more sustainable and ideally circular end-of-life strategy, whether through reuse or recovery or by effective recycling.”

“Delivering innovative, safe and sustainable solutions that enhance the customer experience is our top priority,” said Renee Schouten, VP of marketing for INX International Ink Co. “We want consumers, brand owners, and customers to feel confident in their product choices. That’s why we develop our products to have minimal impact on the environment without sacrificing machine, processing, and end-use product performance.”

Schouten pointed out that INX’s product development efforts focus on material health and safety, product functionality for environmental impact, and consumer safety with a mind for recycle-ready products.

“For example, take a look at our Genesis washable inks for flexo and gravure printing,” Schouten said. “These high-performance inks are designed to make it easier to recycle plastic films and allow for the circular reuse of recovered material. Genesis washable inks are de-inkable from cPET films and floatable with roll-fed OPP labels in the recycling process.”

Zölzer observed that hubergroup takes a holistic view of sustainability.

“This starts by setting high environmental standards in raw material production, which is possible as the majority of raw materials comes from our own Chemicals Division,” said Zölzer “For example, our largest production plant in India operates an own water treatment plant, which allows water recycling of at least 96%. In addition, we rely on energy-saving processes and renewable energy through photovoltaic systems in our production facilities.

“When developing our printing inks and varnishes, we pay special attention to the choice of sustainable raw materials and the recyclability of the end products,” Zölzer added. “To investigate and improve the environmental impact of our products, we partner with the Cradle to Cradle Products Innovations Institute as the approach is comprehensive and rigorous. We offer printing inks with full Cradle to Cradle certification for water-based and solvent-based flexo and gravure printing as well as for offset printing. This means that all these inks are designed for a circular economy and also produced in a sustainable manner.”

Dr. Frischmann said that hubergroup aims at enabling a circular economy, so recyclability is the key topic when developing its liquid inks.

“We are intensively researching on how to positively influence recyclability,” Dr. Frischmann said. “For instance, we investigated the impact of inks on recycling within the PrintCYC initiative. There we found that the binder of solvent-based inks has a major impact on recyclability. While NC (nitrocellulose)-based inks lead to respiratory irritating outgassing and an unpleasant odor as well as color changes of the recyclates in the recycling process, PU (polyurethane)-based inks showed high compatibility with mechanical recycling.

“In addition, we are working intensively on the development of sustainable barrier coatings,” Dr. Frischmann added. “Our water barrier coating, for example, improves the moisture stability of paper and, thereby, facilitates a change from plastic to paper packaging. Our oxygen barrier coating enables mono-film packaging for oxygen-sensitive foods.”

Dr. Wiedmann noted that Siegwerk sees sustainability as the key driver in everything it does, adding that Siegwerk has the ambition to transition itself to a company that has a net positive impact on the environment and society.

“In order to do this in a focused and effective way, we have launched HorizonNOW, our sustainability program with clear targets, dedicated resources and management structures as well as clear accountabilities – also for me as CEO,” Dr. Wiedmann said. “From eco-friendly production processes and the development of safe and sustainable products to inclusive workplaces and local support for the communities we operate in, our sustainability approach is holistic.

“Our overall sustainability agenda aims to keep the effects of our business activities on the environment as low as possible while having a positive impact on the communities we serve,” Dr. Wiedmann added. “To date, we are not only developing circular ink and coating solutions but are also continuously rethinking our own processes and business according to a circular approach. Therefore, we have set concrete targets for reducing waste, lowering energy consumption, increasing resource efficiency and enhancing our products as enabler for packaging design in the context of a Circular Economy – to just name a few.”

Dr. Wiedmann pointed out that Siegwerk is committed to economic and ecological sustainability and are determined to do its part, from an ambitious carbon reduction in operations and supply chain – also affecting the product carbon footprint – to ensuring that Siegwerk only sources from supply chains that are free of environmental misconduct, abuses of human and labor rights as well as corruption.

“We strongly believe in the benefits of a Circular Economy to protect the environment by recycling, reusing, and reducing packaging,” Dr. Wiedmann said. “It is about enhancing the performance and recyclability of packaging to build a cleaner future for next generations. That’s why we are making every effort to further broaden our offering with new innovative and sustainable solutions concretely designed to enable circular packaging. In other words, end use strategies of packaging are already a key part of our sustainability strategy. Next to deinking primers, printing inks and coatings, we also offer a number of technical services along the value chain today supporting an optimized and consistent deinking process. We can also provide optimized deinking chemistry based on a systematic development to ensure fast deinking resulting in clean flakes with almost virgin quality of recyclates. Overall, we are committed to help our customers to cover the final mile to achieve their sustainability goals by offering innovative inks and coatings as well as strategic and operational guidance in the sense of a Circular Economy – this not only includes printers, converters, and packaging manufacturers but also brand owners themselves.”

Edgar Becker, managing director sales for Doneck Euroflex S.A., said the company’s focus on sustainability began years before.

“Since 2018, the entire manufacturing process at Doneck’s headquarters in Luxembourg has been climate-neutral,” said Becker. “This is confirmed by the certified carbon footprint from Climate Partner. Doneck customers can have the carbon footprint calculated for their products. The climate neutral offset was achieved in 2022 by promoting clean wind energy in Brazil.

“Almost the entire ink range of the Clean planet ink series from Doneck Network is based on raw materials that meet at least Cradle to Cradle Bronze status,” Becker added. “The material health certification of the Cradle to Cradle Certified Products Program confirms this. By material health, the C2C principle means environmentally safe, healthy and recyclable materials (technical recycling). In addition, there are numerous raw materials with which the Doneck Network can achieve silver or gold status through appropriate formulations.

Becker noted that Doneck has successfully developed compostable ink series according to EN standard 13431, which meets the requirement for compostability of packaging made of paper, pulp or film.

“Since 2008, 150 of our water- and solvent-based products have been compostable,” Becker continued. “The OK Compost Industrial and OK Compost Home certificates from TÜV Austria confirm this. Doneck is very proud to have achieved silver status in the EcoVadis sustainability ranking at the first attempt.”

“In our experience, sustainable packaging is increasingly in demand,” said Rita Knippel, manager marketing and communications for Doneck Euroflex S.A. “Consumers are buying more sustainably, not only for the product itself, but also for the packaging. In addition, consumers continue to demand high-quality products in recyclable, compostable or biodegradable packaging. For these reasons, our customers in Europe are increasingly asking for alternative and resource-saving products. With our compostable and recyclable printing inks, we are supporting our customers on their way to a green future.”

When we talk about food packaging, the talk quickly heads to regulations. Governments are adding new mandates when it comes to ingredients in packaging, and brand owners sometimes add their own requirements.

Dr. Wiedmann said that the trend observed over the last years is a continuously increasing number of new regulations and a tightening of already existing regulations.

“In addition to that, many international brand owners have their own standards for packaging which go often beyond what is legally required,” Dr. Wiedmann added. “The most challenging task for us as ink manufacturer is to deal with all these non-harmonized obligations.”

“The regulatory landscape continues to change, and with change comes challenges and opportunities,” said Rebecca Lipscomb, director of global regulatory affairs at INX. “Being a global company, INX takes pride in working to meet the regulatory needs of our customers.”

Aldred reported that there are many regulatory activities ongoing in various regions of the world which will affect packaging.

“In Europe under the Green Deal, a wide range of regulations will be relevant to the packaging industry, and The Packaging and Packaging Waste Directive (PPWD) will dictate that certain levels of recycled plastic must be used within packaging materials,” he observed. “Swiss authorities are currently working on a revision of the Swiss Consumer Goods Ordinance, which includes a revision of the ink regulation as well. Worldwide initiatives are in place to regulate or ban harmful substances. For example, the phase out of polyflouroalkyl substances (PFAS).”

Dr. Juhasz said that in an increasingly circular economy when packaging materials are likely to be recycled multiple times and where any substances of concern could potentially accumulate, keeping such material levels in check is important from product stewardship and regulatory standpoints.

“A regulatory issue that we see as a significant topic in the food packaging sector is, of course, the new state-level bans on perfluorinated alkyl substances (PFAS),” Dr. Juhasz pointed out. “Ensuring that all of our products are free of these materials has been a high priority; fortunately, Sun Chemical had already identified suitable alternatives across many of our raw materials. Additionally, from a global perspective, we are following the emergence of the EU’s Packaging and Packaging Waste Regulation, which will shape what is allowed to be put on the market not only for food packaging, but for all types of packaging.”

“Regulatory standards for packaging, particularly food packaging, are impacting us more and more,” Dr. Frischmann said. “At hubergroup, we are, of course, closely observing these changes and realize them in our products. But even beyond that, we are continuously working to develop safe, sustainable, and future-oriented products.”

As a leading wax distributor, Keim-Additec Surface offers a diverse catalog of graphic arts additives, providing innovative solutions through our network of exclusive partners. In 2022, we further expanded this network, adding a new line of natural waxes to the portfolio and debuting several new wax emulsions. Additionally, our team has had success in developing alternatives for PTFE, among other environmentally-conscious initiatives that include streamlining our catalog. With these advancements, our sustainable technology keeps us versatile when it comes to helping clients hone their formulations. Some key features include: