Industry News, Adhesives & Sealants & Tackifiers

New electronic adhesive for delicate structures

Industry News, Adhesives & Sealants & Tackifiers

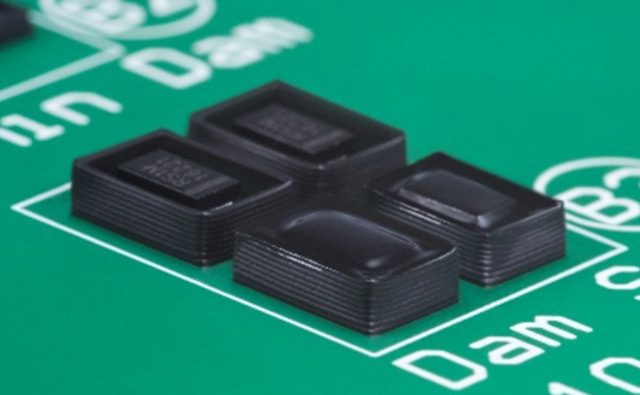

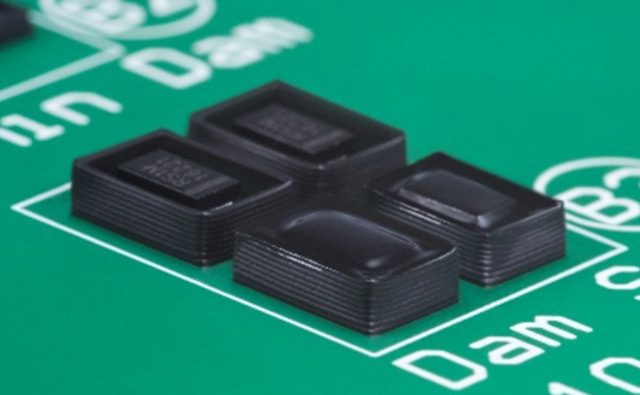

A new electronic adhesive featuring thin and high walls at the same time has been developed for automotive and industrial applications requiring high reliability in combination with miniaturised designs.

“Delomonopox GE7985” has smaller fillers than previous products of Delo’s “dam-and-fill” range, allowing it to be applied with needles of a minimum diameter of 250 µm, which is important given the increasing miniaturisation in electronics. Thanks to a high viscosity of 160,000 mPas, the adhesive provides high flow resistance and an aspect ratio of 2.5. This means that the height of an adhesive bead can be more than twice its width, without the bead collapsing.

These characteristics make the adhesive suited for finest structures such as high separating walls between sensors, for example, which require little width. Stacking of bead layers, known as “dam stacking”, is possible without curing in between. In addition to these design options, the adhesive ensures high reliability. Its properties include an extended service temperature range up to 200 °C, low water absorption, and good chemical resistance to acids, oils, and other aggressive media.

Moreover, the black one-component product has a coefficient of thermal expansion (CTE) of 24 ppm/K, which, combined with the high glass transition temperature of 180 °C, keeps warping at a low level over a large temperature range, thus minimising stress to the package. Finally, it features good strength on the FR4 PCB material, reaching a compression shear strength of 49 MPa. This value changes very little even after 500 hours of storing at 200 °C, it is still at 43 MPa.

The adhesive cures under heat with variable conditions in terms of time and temperature, for example, 20 minutes at 150 °C or 90 minutes at 125 °C. Thanks to the adhesive’s flow resistance, the aspect ratio does not change during this process, so the height of the adhesive bead remains the same after heat curing.