Industry News

Biobased Resin Technology: Helping Define High Performance

Industry News

Link: Biobased Resin Technology: Helping Define High Performance | PCI

By: Dr. Jamie Dziczkowski

Waterborne technology continues to be the prime focus of emerging coatings markets while the attributes required for designation of a “green” coating continue to adapt. With more options available to achieve high-performance products, green has come to identify with resins that are low VOC, low odor and alkylphenol ethoxylate (APE) free. However, as the coatings market continues to expand, it is becoming more difficult to differentiate from competitors that offer similar product lines.

Based on this, more companies are adding and/or expanding their portfolios with biobased waterborne alternatives that offer the formulator/end user another benefit without sacrificing performance. Products that contain biobased functionality perform equivalently to their petroleum-based counterparts, but are composed entirely, or in significant part, of biological products, renewable agricultural materials (including plant, animal and marine materials), or forestry materials. These materials still offer low VOC, low odor and are APE free, with an added bonus of being partially derived from a renewable raw material source.

Using biobased products manufactured from domestically produced biological feedstock can reduce our dependence on imported energy sources and our nation’s reliance on petroleum. Additionally, products that come from biologically produced carbon-containing material may contribute to reducing the amount of new carbon released into the atmosphere, thereby enabling us to better manage the carbon cycle.

The coatings industry has worked to define requirements needed to be classified as eco-friendly, yet still provide the consumer with high-performance products. Most certification/labeling programs that the consumer identifies with for the coatings industry are focused on chemical exemptions, VOC limits, performance requirements and packaging constraints. Today, several independent green certification processes such as Green Seal® and Green Guard® are well established, with strict environmental components. A variety of products are available that conform to these requirements but, moving forward, are there other considerations that should be accounted for that distinguish one product from another and provide the manufacturer with a market advantage?

The USDA BioPreferred® Program is a recent option for product labeling. Unlike other green certification programs, its main function is to encourage an increase in the use of renewable agricultural materials. This program was initially introduced and funded in 2002 through the Farm Security and Rural Investment Act, more commonly referred to as the 2002 Farm Bill. It was redefined in 2008 into distinct product categories that can benefit from and traditionally utilize biobased materials. In an effort to standardize this classification, a certified test method performed by outside laboratories was created to sort materials according to their renewable carbon content. ASTM D6866, Test Methods for Determining the Biobased Content of Solid, Liquid and Gaseous Samples Using Radiocarbon Analysis, was developed to support the biobased certification program. This special method uses radiocarbon dating to determine the amount of new carbon present in a product as a fraction of the total organic carbon.

The BioPreferred Program is comprised of two distinct initiatives. The first initiative, the procurement program, operates with defined categories that are required for purchase by Federal agencies and their contractors. As these categories are designated, minimum biobased content is specified. Currently, there are 97 BioPreferred designated product categories. The product categories are organized by “rounds” in which they were introduced and by functional area. The majority of predefined categories that have the most impact on the coatings market fall under the functional area of “Construction”.

Specific categories that pertain to coatings companies are Interior Paints and Coatings: Latex and Waterborne Alkyd [20% minimum renewable carbon content (MRCC)]; Oil-based and Solventborne Alkyd (67% MRCC); and Wood and Concrete Stains (39% MRCC). The second initiative, voluntary certification and labeling, provides the consumer with biobased products that meet the BioPreferred program requirements. For products that do not fall into a designated category, the minimum biobased content is 25%. This option should include all of the intermediates that go into coatings formulations, including resins and additives. Currently the USDA is working out details on how to handle intermediate materials that contribute to the finished product. For more detailed information on the BioPreferred program, visit www.biopreferred.gov.

As businesses and consumers become more familiar with biobased products, and their acceptance in the marketplace continues to expand, it is imperative to educate the coatings market on the benefits of using a biobased system. For starters, biobased waterborne resins show comparable performance to their non-biobased counterparts and traditional solventborne coatings. Examples of performance comparisons will be covered in greater detail later in this discussion. Additionally, most biobased polymers are cost competitive with competitive chemistries on a solid resin basis. Also, because biobased materials are readily available, renewable, and not dependent on the fluctuating prices of petrochemicals, their price points tend to be more stable.

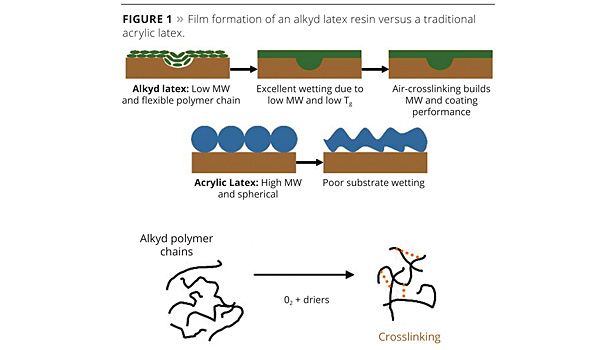

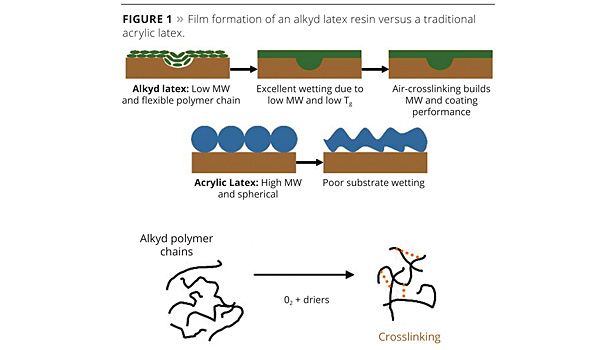

Understanding performance benefits of a biobased material requires an insight into the chemistry surrounding biorenewable materials. Biobased coatings resins typically refer to alkyds, which are oil/fatty acid-modified polyester resins and oil-modified urethanes/uralkyds (OMUs). Other resin chemistries can include modifications with biobased materials, but are less common. Both alkyd and urethane technologies have been in use for many decades and are a popular choice in solventborne coatings chemistry. However, with stricter VOC allowances and environmental profiling, solvent-based coatings are a fraction of the market relative to what they were 30 years ago. Much like other resin chemistries, the ability to convert from a solventborne to a waterborne vehicle with corresponding performance has been a challenge to researchers. Nonetheless, there are a number of companies that offer water-based versions of the biorenewable resins that provide these performance characteristics. The main performance benefit of a biobased resin is its ability to self-crosslink after solvent evaporation through the oxidation process. Fatty acids commonly used in alkyd and OMU chemistry contain unsaturation sites that, when exposed to air, will form interchain crosslinks over time. Both alkyd and uralkyd solventborne systems build the majority of their molecular weight through the oxidation process. Because of this, they have a lower initial molecular weight. They offer good flow and leveling characteristics and good interchain diffusion.

Figure 1 depicts the alkyd latex film formation process versus a traditional waterborne acrylic.

Alkyd latex resins have the same film formation profile as solventborne biobased resins because of their lower initial molecular weight. Figure 1 depicts the alkyd latex film formation process versus a traditional waterborne acrylic. Waterborne uralkyds, more commonly referred to as polyurethane dispersions (PUDs), are a completely different phenomenon. Because most PUD resins have a very high initial molecular weight, coalescence of the final film can still require higher levels of solvent. By providing the polymer a self-crosslinking mechanism through fatty acid modification, performance properties, such as mar and solvent resistance, can be achieved at lower VOC levels. A representation of a post crosslinking polyurethane coating is shown in Figure 2. Now with both alkyds and oil-modified urethanes available in low-VOC, low-odor, APE-free waterborne systems, they bring a distinct advantage to the formulator.

Figure 2. Now with both alkyds and oil-modified urethanes available in low-VOC, low-odor, APE-free waterborne systems, they bring a distinct advantage to the formulator.

Alkyds have dominated the coatings market for many years because of their good overall performance, ease of application and low cost. They can be used in a variety of architectural and industrial applications. However, because traditional alkyds were available in organic vehicles, the need for lower-VOC coatings challenged researchers to develop alkyd-based systems with equivalent properties to high-VOC materials.

High-solids alkyds encompassed traditional alkyd chemistry at lower initial molecular weights in stronger solvents, but were typically short on performance. Additionally, this approach could only take the technology to a minimum VOC that has since been lowered by stricter limitations. Several waterborne alkyd technologies, including water-reducible alkyds, alkyd dispersions and alkyd latexes, followed. The first-generation waterborne alkyds showed great performance, but because of an alkyd’s tendency to hydrolyze, stability and shelf-life were a challenge. However, as greater knowledge of waterborne resin chemistry evolved, and advancement in surfactant technology was readily available, several manufacturers began offering waterborne alkyds that encompassed a range of alkyd classes that have excellent stability and offer similar or superior performance to their solvent counterparts.

Reichhold offers high-performance, next-generation alkyd latex products that bear the trade name BECKOSOL® AQ. There are currently eight products featured in the commercial line. End-use applications range from wood stains to trim enamel to industrial and architectural primers. All resins carry the voluntary BioPreferred label with biorenewable contents ranging from 34-68%, depending on the resin. The most recent addition to the product line is a specialty resin used for concrete sealer applications. BECKOSOL AQ 521 is a low-VOC, epoxy-modified alkyd latex intended to provide excellent penetration and substrate wetting. This material is roughly 54% renewable carbon, verified by ASTM D6866. When formulated, the final product delivers an unparalleled wet look finish for porous concrete and masonry surfaces by enhancing the natural color of concrete pavers without imparting gloss. Coatings can easily be applied by DIY and professional applicators.

The product development of BECKOSOL AQ 521 is a prime example of how biobased chemistry can be used to reach solventborne performance with the latest resin technology. Several waterborne selections at less than 100 g/L were screened against existing waterborne and solventborne commercial products. Water-soluble oils, polyurethane dispersions, alkyd dispersions, epoxy-ester dispersions and alkyd latex resin technologies were all considered. There were six commercial controls that ranged from ~100 g/L to roughly 700 g/L and 20-33% weight solids. Resin candidates were screened in a standard formula that was adjusted to 25% weight solids with only resin, driers to catalyze oxidation and water. Gloss, adhesion, abrasion and chemical resistance, weathering exposure and delta L (a measure of the lightness/darkness of uncoated paver versus coated paver) were evaluated for all materials.

Figure 3 shows the highest performing commercially available solventborne

The high performance of the biobased latex resin is more obvious with a graphical comparison of the three technologies. Figure 3 shows the highest performing commercially available solventborne, the highest performing commercially available non-biobased waterborne and the new biobased waterborne alkyd on different substrates, while Table 1 provides a summary of the performance data.

Table 1 provides a summary of the performance data.

Based on this testing protocol, the data demonstrates that BECKOSOL AQ 521 sealer at ~70 g/L performs closely to the solventborne control, which is well over VOC limits at over 700 g/L. A very key piece of information in the adhesion test was the improved wet adhesion of the biobased waterborne option over both commercial controls. The new biobased wet-look sealer was the only one to fail by concrete failure. Both the non-biobased waterborne and the solventborne coatings had cohesive wet adhesion failure. Chemical resistance, abrasion resistance, water spot absorption and gloss are similar across all resin classes. The delta L value of the commercial waterborne control is much lower than the other two systems. This is just one example that demonstrates the high-performance, low-VOC characteristics of a biobased resin alternative.

Alongside alkyd chemistry, polyurethane chemistry is a much practiced technology. There are several classes of polyurethanes, both one- and two-package coatings that range from soft, thermoplastic elastomers to hard, thermosetting coatings and rigid insulating foams. The main components of polyurethanes are isocyanates and glycols. The particular class of polyurethane that will be the scope of this discussion are oil-modified urethanes or uralkyds. These coating binders are one-component polymers that have no free isocyanate groups and have been reacted with oils to introduce pendant fatty acid moieties so that the resultant polymers may self-crosslink by oxidation at room temperature. Applications for polyurethanes range from use on wood, metal and concrete substrates to use for plastic coatings to leather substrates. Like alkyds, first-generation urethanes were supplied and manufactured into finished products at very high VOC levels. Researchers in this chemistry also attempted high-solids versions with lower-molecular-weight polymers, but were once again limited to a minimum VOC level for balance of performance properties.

Polyurethane dispersions were then developed to meet the lower VOC requirements, but still offer desired performance. PUDs are formed by a three-step process: 1) formation of the intermediate/prepolymer through reaction of the isocyanate/glycol components, where one of the glycol monomers contains residual acid functionality to make the system readily dispersible in water; 2) neutralization and dispersion of the prepolymer; 3) chain extension carried out through the isocyanate/amine reaction.

Biorenewable content is achieved with a fatty acid-modified glycol monomer incorporated into the prepolymer. Although PUD resins are predominantly supplied in water, they still require the use of cosolvent, typically n-methylpyrrolidone (NMP), to reach the desired amount of coalescence for required performance. But, as VOC limitations continue to drop and NMP is on the radar for inhalation hazards in certain markets, the use of this particular cosolvent is discouraged. Today, certain manufacturers offer polyurethane dispersions with alternate cosolvents or that are cosolvent free.

UROTUF® F100-W-36, a self-crosslinking PUD, is one example that provides the formulator a cosolvent-free option for wood flooring and other various applications. The resin, as supplied, contains 52% renewable carbon content verified by ASTM D6866 testing. Performance characteristics include quick dry, excellent stain and chemical resistance, and good mar and abrasion resistance. Because this resin is supplied without a cosolvent, the formulator has freedom to choose lower-toxicity coalescing solvents.

In a clear sealer, UROTUF F100-W-36 provides the contractor a finish with equal performance to traditional solventborne clearcoats with the option for multiple coats in the same day. Cosolvents that are recommended with the resin for industrial use include dipropylene glycol monomethyl ether (DPM), tripropylene glycol monomethyl ether, propylene glycol monopropyl ether, propylene glycol monobutyl ether and isobutanol. Depending on solvent choice, the time to reach the desired mar resistance using a fingernail scratch test will vary. Table 2 shows performance comparison of UROTUF F100-W-36 versus a high-VOC commercial oil-modified urethane at high VOC and a commercially available high-solids OMU at lower VOC. Please note that all values reported with the UROTUF F100-W-36 were formulated to 175 g/L with DPM.

Table 2 shows performance comparison of UROTUF F100-W-36 versus a high-VOC commercial oil-modified urethane at high VOC and a commercially available high-solids OMU at lower VOC.

From the data, it is clear that the UROTUF F100-W-36 offers equal performance to the non-compliant solventborne formulation. One of the challenges for researchers has been to get the desired mar resistance within 24 hours. This new solvent-free, biobased alternative offers that along with improved drying times. One of the key components when formulating a self-crosslinking PUD varnish is the use of oxidation catalysts to achieve desired performance. It has been determined that with these systems, maximum performance, especially mar resistance, is most easily achieved by allowing the formulated coating to equilibrate for seven days at ambient temperature. Good hardness development, excellent chemical resistance, and abrasion resistance required for wood flooring and other applications are all achieved by formulating with the biobased PUD. As pointed out earlier, the high-solids, lower-VOC solventborne OMU falls short on performance compared to both other systems shown in the table.

Biobased materials are becoming more accepted as the coatings industry continues to grow. Formulators are experiencing the high performance characteristics that this self-crosslinking technology brings to the finished product. Not only does the biorenewability make the resin component more eco-friendly, but it allows formulators to achieve that high performance at lower VOC levels. The versatility of the product lines focused on in this publication are just two examples of several biobased products that are offered by a variety of manufacturers that are helping key industry players differentiate themselves.

The author would like to thank the following individuals for their technical contribution to the publication: Jennifer Hall, Alan Toman, Shi Yang, Kristy Hayes, Rob DeRuiter, and Bryan Naderhoff.

For more information, visit www.reichhold.com.